The Contrôle Officiel Suisse des Chronomètres (COSC) is crucial to the Swiss watch industry. It’s existed in its current form since 1973 but there has been competitive chronometric testing happening in Neuchâtel since the late 1800s. Today, the COSC functions as a sort of litmus test for precision throughout the Swiss watch industry. In an era when any watchmaker worth his salt has a timing machine (Witschi produces the most popular ones) that can measure accuracy immediately, the certification doesn’t necessarily have the same “wow” factor it once did. That being said, it’s still a valuable aspect of how the Swiss watch industry conducts its business and, due to the intense trial each movement goes through, it’s a tried-and-true way of demonstrating the quality that Swiss mechanical watches are known for.

1.) Only “Swiss Made” watches can be submitted for the exam. The oft-debated label demands that the watch’s movement is Swiss, the movement has been cased in Switzerland, final tests are run there, and at least 60% of the production costs are generated in Switzerland. Further, a Swiss movement has to be assembled and tested in Switzerland, at least 60% of production costs are generated in Switzerland, and the value of 50% of the components are Swiss made. The main reason for the exclusion of other countries is that since the COSC functions as a non-profit, this helps ensure both the prestige and caliber of both the certification and the Swiss watch industry as a whole. There is zero doubt that watches made in Japan and Germany could pass the exam — those countries have their own qualification test with similar rigorous guidelines. But isn’t there something just so Swiss about the country having its own personal watch testing facility that functions “as a public service.”

2.) To have a watch pass the certification, the movement must be sent to one of the COSC labs where it immediately goes through the following: tests the numbers engraved on the movement (in relation to the list supplied by the applicant), the movement is placed in a 5-slot clasp, the movement is wound according to the brand’s supplied guidelines, and the parts are placed in a temperature controlled enclosure for 12 hours at exactly 73.4°F (23°C). Then, over the next 15 days, the parts of the wristwatch go through daily tests. Each day, the clocks and watches are measured and reassembled. At the end of that time period, the wristwatches are judged by seven different criteria: average daily rate, mean variation in rate, greatest variation in rate, the difference in rates in horizontal and vertical position, largest variation in rate, and variation in rate depending on temperature and rate resumption. You can see the exact specifics below. If the watch passes these guidelines, it is officially awarded the certification.

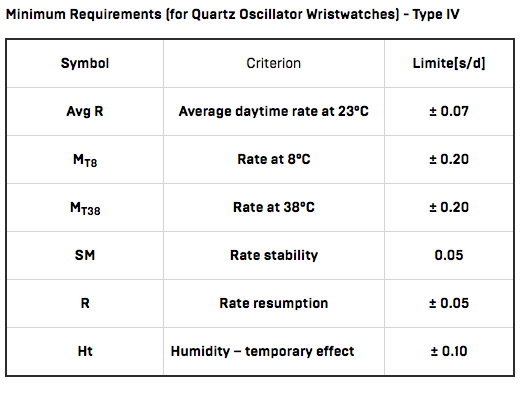

3.) The COSC doesn’t just measure mechanical wristwatches, they also measure pocket watches, fixed time devices such as onboard instruments and carriage clocks, and quartz timepieces. There is currently no international standard for measurement of a watch with a quartz oscillator, so the one used by the COSC is based on the same ISO 3159 standard used in their measurement of mechanical wristwatches. All COSC-certified quartz timepieces must be thermocompensated which is a necessary feature of the high-accuracy quartz (HAQ) designation. This means that the movement can adjust automatically to the frequency of the oscillator according to the ambient conditions. It also must be completely watertight to keep moisture out. Each quartz chronometer is tested for 13 days in one position — compared to 15 for wristwatches/pocket watches and 19 for onboard clocks — at 3 different temperatures, and 4 different humidity levels. As you can see below, there are less total categories than what mechanical wristwatches/pocket watches are tested for, but the rate levels are much stricter.

4.) The COSC is spread out among three separate testing laboratories that employ 60 full-time staff members and 70 auxiliary employees. The three laboratories are located in Biel/Bienne, Saint-Imier, and Le Locle. It has to operate seven days a week to keep up with the constant testing guidelines mentioned previously and 350 total days a year. Over 1.6 million watches are certified every single year, a figure that has grown substantially over the decades. In 1976, when the current iteration of the COSC was founded, only 200,000 watches passed the exam. Fast forward to the year 2000 and there were one million chronometers that completed the exam. Out of all watches exported from Switzerland, only 6% are COSC certified. Out of all mechanical Swiss watches that are exported, 21% are COSC certified.

5.) According to a report from 2015 — which is the last year that the COSC will publish the exact figures citing a request from the brands to protect their confidentiality — the three companies that receive the most COSC-certified timepieces aren’t all that surprising. Rolex is numero uno with 795,716 watches, Omega is second with 511,861, and Breitling is third with 147,917 total timepieces (28,499 of those are quartz models). Next up are two of the more accessible brands in the Swatch Group, Tissot (96,563) and Mido (49,962). There’s a sharp drop off in total number for the rest of the top ten with Tudor (23,003), Chopard (16,107), Zenith (6,824), Panerai (6,262), and Bremont (5,860) rounding it out. Ball Watch Co. (5,031), Carl F. Bucherer (4,577), Titoni (4,146), Christopher Ward (3,362), and Ulysse Nardin (2,561) make up the next five. However, as I mentioned previously, we have no way of updating these figures to see how the production of COSC certificates has changed in recent years.

Click here to read about five affordable chronometer-rated watches.

The COSC average +- rate has been lowered over the years, meaning to pass the COSC testing today is much easier than in the 1950’s. If true, that was not mentioned in your article. Also you do not state what Level 1 and Level 2 is reffering to. I for one would like to know.

i have a question. once certified, if the watch undergoes maintenance or repairs by the manufacture, does it lose the certification or is it always certified

Anyone have thoughts on the COSC-certified Longines Record? I purchased mine 8 months ago and it’s been back for repairs twice because it runs above the certification. It’s still running too fast, but I am hesitant to send it back for a 3rd time since they don’t seem to want to fix it and I’ve spent more time without my watch than with it.

Need to mention that @PatekPhilippe decided by its own Quality Seal instead based on 10 evaluation procedures.

Other than PP started their own , I wonder about the reason for the top two Swatch Group brands being absent and are A Lange’s produced mainly in Germany?

Hi, I’ve heard something about Omega quality seal in terms of precision (as Patek does) that is going to replace the “old” COSC certification. What about?

Your article is very informative and educative.

Interesting article. So it’s not just a prototype that gets passed and then all other watches are produced that way. Each and every single watch gets tested individually?

Regards,

Nicolas

Hi Nicolas,

Yes, every watch that receives the COSC certification has gone through the individual exam.

So, do Patek Philippe not bother with being COSC certified? Seems strange.

Hi Butch,

Patek Philippe uses a different quality seal. You can read more about it here: https://www.watchtime.com/wristwatch-industry-news/industry/patek-philippe-create-quality-seal/

Thanks for commenting!