The independent brand from Biel, Switzerland has one of the highest levels of vertical integration in the industry.

If you have the opportunity to visit a watch factory, you will no doubt see many different operations being performed by different machines and people with different specializations. Only at Armin Strom, however, will you see all these tasks being performed in such a compact space at one of the industry’s smallest, yet no less capable, “manufactures.”

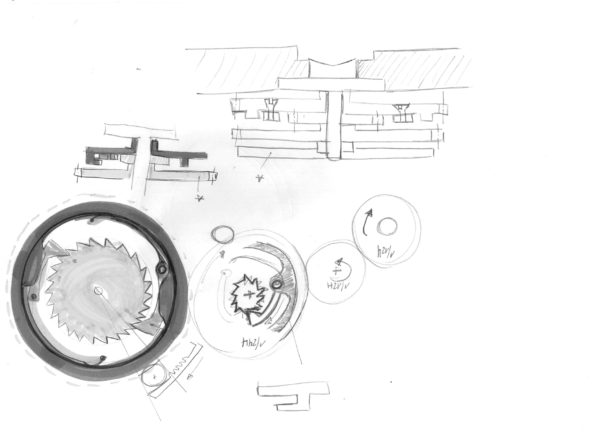

No new watch movement would ever see the light of day, however, were it not for the original ideas of the engineers and watchmakers behind them. In the case of Armin Strom, it is Claude Greisler who puts ideas such as the one for the revolutionary Mirrored Force Resonance movement down on paper before they are transferred to computer-aided design programs to start modeling the movement.

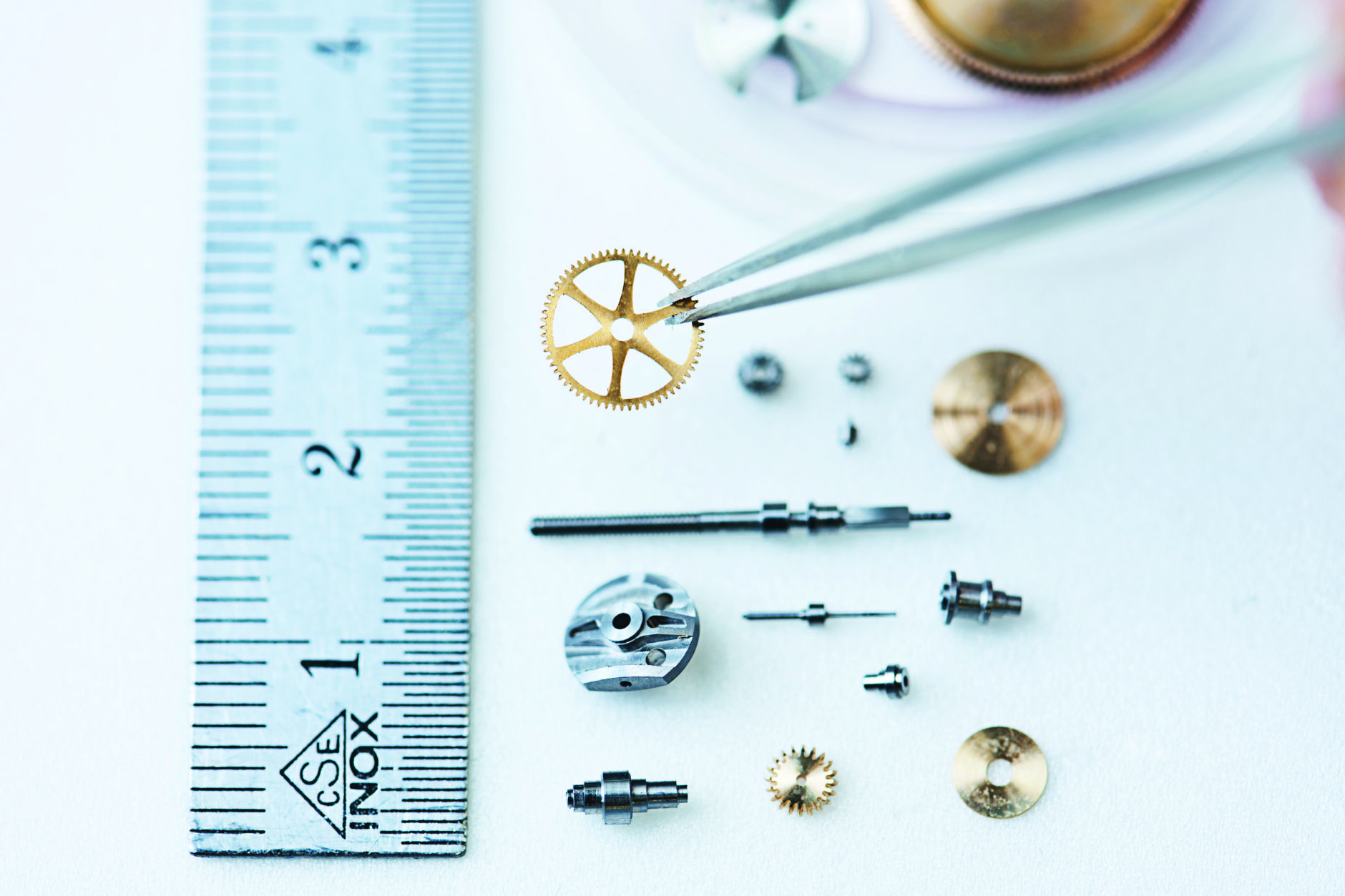

Like so many things at Armin Strom, all of this is done in-house, with the dimensions calculated down to a precision of one micron to provide the inputs for the machines that will eventually produce the minutest of components.

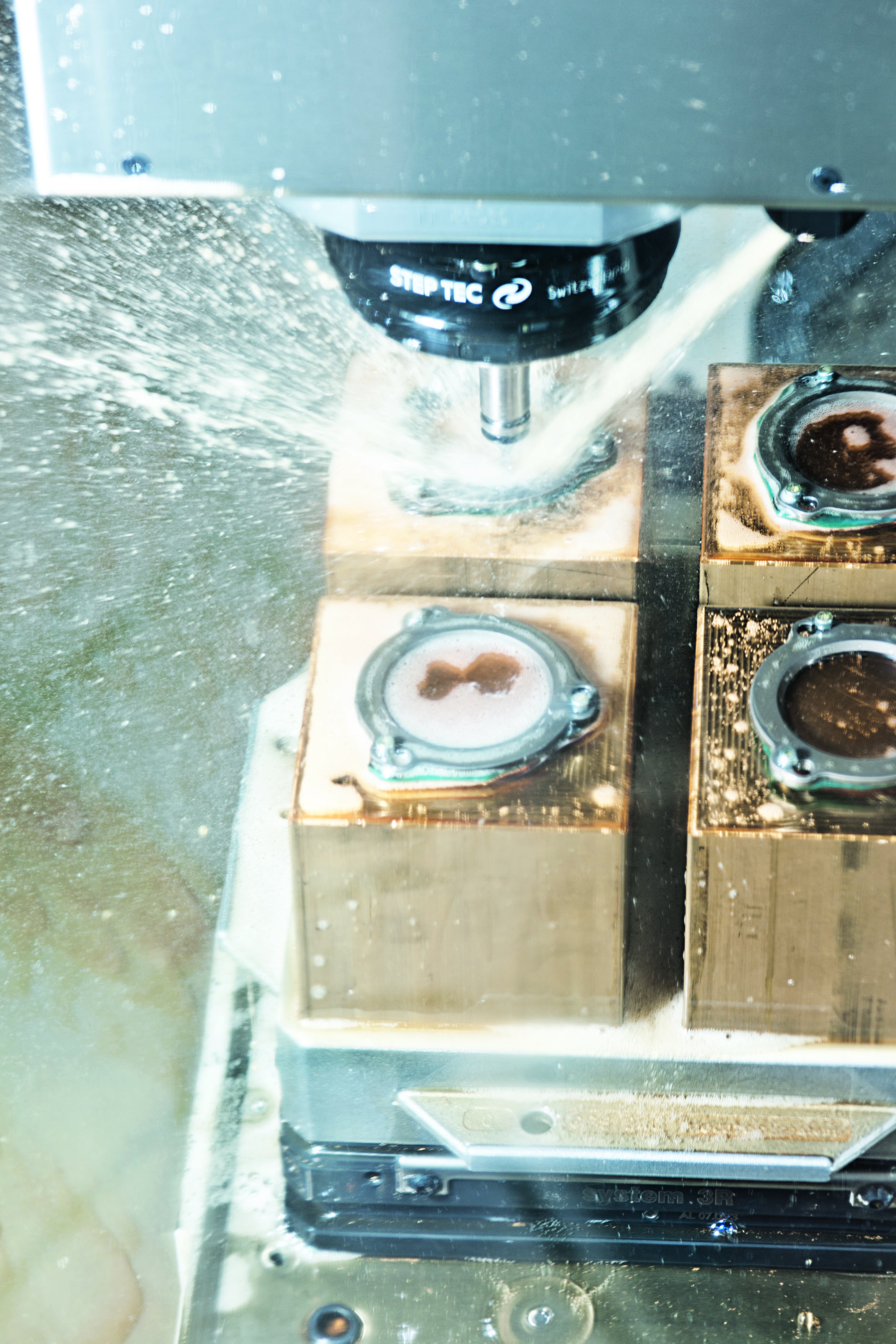

At Armin Strom, the majority of components in the movement, with the exception of the escapement and balance spring, are produced in-house. Small round components, such as screws, pinions and gear wheels, are produced by profile-turning machines, which gradually whittle-away long steel or brass rods from the side to cut teeth or axles. Larger components such as the mainplate and bridges are produced from brass on CNC machines, which are capable of machining along multiple axes consecutively using different tools for different operations, moving the component using robotic arms.

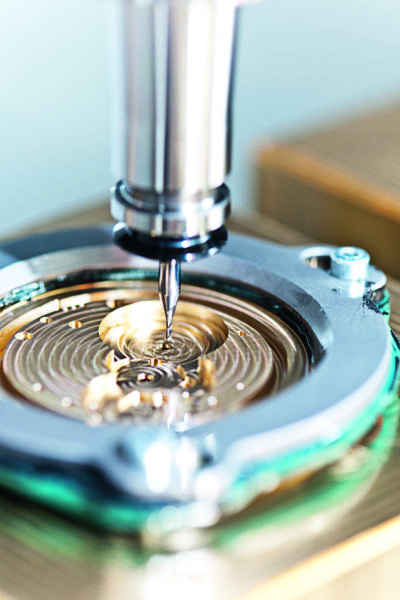

Particularly small and delicate components, such as smaller bridges, levers, and springs, are produced using wire erosion. This involves threading a wire that is not much smaller than a human hair through a tiny hole in the metal. An electrical current running through the wire reacts with a solution in which the entire working plate is dipped, thus “eroding” minuscule amounts of the metal. This allows particularly delicate operations to be carried out while maintaining the structural integrity of the metal. In fact, Armin Strom does not produce any of its components by stamping because of the stresses that this places on the metal.

Once the raw components are fabricated, they are engraved, beveled, polished and decorated with circular graining or Geneva stripes by hand before moving on to the in-house electro-plating department. Here, all steel and brass components are first given a gold plating before a layer of nickel is added to prevent corrosion and harden the surface.

After cleaning, the parts are then dipped in other electroplating baths to give them their final color such as rhodium, ruthenium or rose gold. It is only thanks to its mastery of electroplating techniques inside its own workshops that Armin Strom can allow customers to choose their preferred colors for the coating on different components.

Only then can the individual components of the movement be passed on to the watchmaker for assembling. After setting the jewels into the mainplate and bridges, the gear train and mainspring can be added. Once the escapement and balance wheel are added, the movement finally comes to life… only to be completely disassembled, cleaned and dried before being re-assembled and lubricated. After several days of testing the precision, the watch is finally ready for the customer.