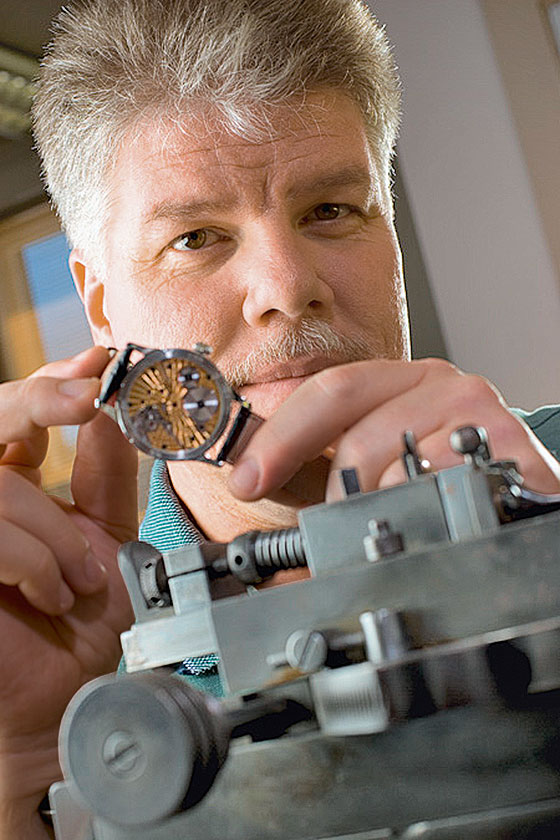

Making a watch movement in Switzerland is one thing. Making one in the USA is quite another. Just ask Roland G. Murphy, founder of RGM Watch Company. We spoke with Roland Murphy and took an in-depth look at his highly respected portfolio of RGM watches.

You might chalk it up to Millennium fever. It’s hard to know. But at the beginning of the last decade, Roland Murphy had a crazy idea. A literally crazy idea, many said. Baltimore-born Murphy, a WOSTEP-trained watchmaker turned watch manufacturer, founder and owner of RGM Watch Co. Inc., decided that he wanted to make a mechanical watch movement right here in the good ole U.S.A. Making an exclusive, high-grade mechanical movement is a major undertaking. Swiss watch executives will tell you it takes an investment of many years and oodles of francs. Roland Murphy doesn’t have oodles of francs or dollars. Watch-wise, he’s a small fry. Worse, he’s an American small fry. He doesn’t have the clout and contacts in Swiss watch circles that big-name Swiss brands do. He and his small team (RGM employs fewer than a dozen people) make 200 to 400 RGM watches a year in a former bank building in little Mount Joy, PA, in horologically historic Lancaster County.

What Murphy does have, though, is mega-doses of American ingenuity, stick-to-it-iveness, street smarts and stubbornness. It took him about eight years but, against all odds, Murphy did indeed make an American movement. In 2008, he introduced the RGM Caliber 801, which he says is the first high-grade mechanical watch movement made in America in four decades. Murphy followed it up in 2010 with the RGM Pennsylvania Tourbillon, containing RGM Caliber MM2 (for “manufacture movement 2”), with a tourbillion mechanism made in Lancaster County. This year, RGM celebrates its 20th anniversary with a new tonneau watch containing the firm’s third movement (and first shaped one), Caliber 20. All of the Pennsylvania-made movements are stamped “USA,” denoting the country of origin. Just what possessed Murphy to try and make a mechanical movement here and how did he do it? To find out, WatchTime met with him at RGM’s workshop and headquarters at 801 (yep, the movement is named after the workshop address) West Main Street in Mount Joy, situated in Pennsylvania Dutch country west of Lancaster.

The answer to why he did it is simple. “As a watchmaker,” he says, “somewhere deep down is a little voice that says, ‘I have to make watches. I have to produce movements, and I want to do it here.’ To really be a watch company, you need to make your own watch. Otherwise, you’re a casing company. I don’t want to be a watch-casing company. I want to make our own movement, our own complications, our own hand-finishing. It’s a love, a passion.” Murphy wanted to make a distinctively American movement. “I take my inspiration mainly from American watchmaking,” he says. He’s a fan of classic pocketwatches from America’s late 19th-century and early 20th-century heyday, like those from Howard, Illinois, and Hamilton. (It was Hamilton, which manufactured mechanical watches in Lancaster from 1892 to 1969, that put Lancaster County on the watch map. Murphy worked at Hamilton early in his career.) The caliber of his dreams was manual-wind, 16½-ligne, nearly pocketwatch-sized. It would have a thick, sturdy bridge like that in a 1915 Edward Howard watch, a winding-wheel click like that on an Illinois watch from the 1920s, and traditional finishing throughout.

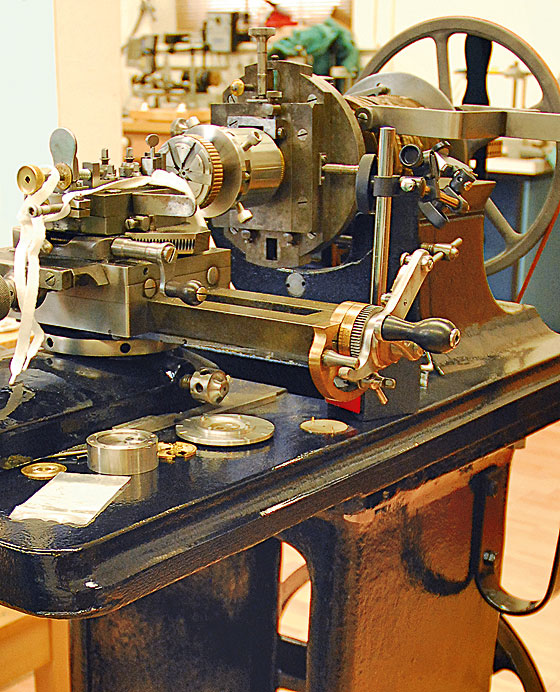

Murphy could dream about having his own movement because advances in micro-mechanical engineering transformed mechanical watchmaking in the last two decades of the 20th century. CNC (computer numerical control) machines, EDM (electric discharge machining) wire erosion and laser micro-machining made it possible for an artisanal watchmaker like him to try his hand at his own movement. Says Murphy, “Those techniques made it more affordable to someone who is creative.

“But,” he continues, “there is a big learning curve. When you go to school for watchmaking here or at WOSTEP in Switzerland, the program is mainly aimed at training individuals to service watches, after-sale service. It’s not aimed at manufacturing. I went to Bowman Technical School here in Lancaster. We learned to make a few things, but it was always aimed at repairing and restoring, not at manufacturing. I wanted to try but I wasn’t sure I could accomplish it. I had to teach myself, with the help of others, to understand the capabilities of the new technologies. I had to learn what we can do with wire erosion. What can CNC do for me? What kind of materials and equipment would I need? What’s it going to cost? So I had a disadvantage. If you want to make a watch, and not just repair it, there’s a piece of the puzzle missing.”

Originally, Murphy had hoped to find the missing piece of the manufacturing puzzle in the capital of mechanical watchmaking, Switzerland. He took his rudimentary drawings for his own movement to a Swiss firm that produces machinery for making watch bridges and plates. “They weren’t very helpful,” he says. There were two problems: one, his quantities were too small; two, he was a foreigner. “They were interested in making money. If your quantities are high enough, they’ll turn the machine on. But if not,” he says with a laugh, “it’s ‘Have a nice day.’” That experience made him bound and determined to make his movement in America. “I came back here and I hunted. I knew we had technology. I just had to find somebody who was willing.” He found a micro-manufacturing company five miles from Mount Joy that produces parts for applications in the aerospace, medical, and pharmaceutical industries. He met with the owners, but they, too, showed little interest. “After talking with them a few times, it didn’t go anywhere. If somebody is not eager at the beginning, you might as well just keep walking.” So Murphy walked.

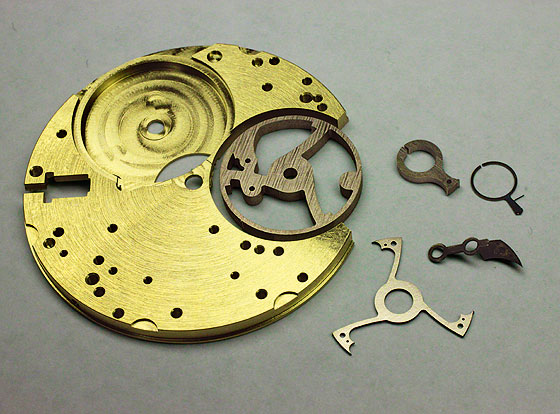

A while later Murphy noticed a new corporate name on the building. The company had changed hands. Murphy stopped in, met the new owners, and exchanged a few e-mails. “I could tell they were interested in what I was doing,” he says. “They liked the challenge. They said, ‘Yeah, we can do that. There’s nothing here size-wise or tolerances-wise that our machines can’t do.’” The company, 45 employees strong, has millions of dollars’ worth of CNC, wire-cutting, and other manufacturing equipment. Murphy asked them to make 10 sets of bridges and plates for his 801 caliber. “Just to see where we were,” he says. They agreed. (“Nobody in Switzerland would make 10 sets for me,” he notes.) “I knew the parts probably wouldn’t be good, but I wanted to see where I was physically. We made 10 sets and then I could sit down with those sets and see where there had to be changes. I’m used to working with things in my hands. So, working with those parts, I would take notes, and saw there were numerous things that would have to change. I made a number of changes over a period of a year before we ran any more parts.

“At the beginning they were doing the 3-D models for me. I would go down there and sit with them for hours, doing drawings, making changes, because I was the only one who knew anything about watches. They were very patient through all that. I’m sure there were many hours they didn’t charge me for. They were really behind the project. “Then, about a year later, we ran 20 sets of parts to test. And with those, I was able to get a watch running with some modifications I did here in the shop. I could go to the jig board and make a little change. “It took a lot longer for me to have the 801 the way I wanted it because it was my first venture into manufacturing. I spent a lot of money on parts I couldn’t use. We realized afterwards, ‘Hmm, no, I’ve got to change this and that’ and then we’d go back to the drawing board.” Nevertheless, Murphy’s Caliber 801 was beginning to take shape with bridges, plates and other small components made in Lancaster County.

Some things, though, you just can’t get in Lancaster County no matter how enterprising you are. “We can manufacture a balance wheel here,” Murphy says. “And we’re now at the point where we can make an escapement. But what we can’t do is manufacture the hairspring.” For that Murphy needs the Swiss. The Swiss, however, as we saw, don’t need him. Nivarox, the primary supplier of Swiss watch escapements, won’t sell to Murphy so he is forced to buy what the Swiss call the assortment (escape wheel, pallet and balance with the hairspring) “sideways,” as he puts it. “I get a small quantity through a third party. There are a few roadblocks here and there. Sometimes I have to pay a little more. The important thing is that we get the parts.” The hairspring roadblock he expected. It was the Geneva wave roadblock that caught him by surprise.

Murphy’s tastes in watch and watch movement design are decidedly classic and he was determined to have his 801 movement decorated with classic Geneva waves (Murphy favors the French expression for them, côtes de Genève). So he went to Switzerland to find a machine for producing Geneva waves. Due to budget constraints, he hoped to buy a used one. To his chagrin, he learned that the mechanical-watch boom has driven demand for pre-owned Geneva-wave-makers through the roof. “I’ve got a list of 30 people looking for one of those machines,” one Swiss tool company exec told him. “I’ll never have one for you.” Stymied, he looked at new machines. The cheapest one, a semi-automatic, was $15,000. Murphy was aghast. When he discovered a small manual one, his heart leapt. “I was thinking, ‘It’s manual; it’s got to be less, right?’” Wrong. It cost $20,000. “With all the other things we had to do, it was cost-prohibitive,” he says. He came home empty-handed.

He mentioned his problem to a friend in nearby Manheim, PA, a machinist who works for a medical equipment company. “He’s their machine guy,” Murphy says. “He fixes machines, restores them, sets them up. He’s a machining wizard. He said ‘Let me think about this.’” The friend mulled it over and came up with a solution: a made-in-America Servo drill press that he had at home. The machine wizard attached the press to a sliding sled that moves backwards and forwards. Then he hooked compressed air to it, which helps regulate the speed and consistency of the motion. Murphy supplied the proper 3M abrasive paper (he’s since switched to a brand that Swiss watch firms use) and, voilà, a home-made côtes de Genève maker. It worked so well that Murphy bought his own Servo drill press on eBay for $2,000. “Nice little thing,” Murphy says, “made of a mill base, so it’s really solid.” His friend converted that drill press into a Geneva-wave machine, too. “Instead of spending $15,000 or $20,000, I have $3,600 in this machine and it works awesome,” Murphy says. “But it took time to figure all of that out.” He’s also proud of his Nikon optical comparator, used to inspect and measure components. “It’s probably 25 years old, but it’s in beautiful shape. I got it for $1,700; a new one is probably 15 grand. It works great.”

Murphy’s team does their own perlage, or circular graining, on the movements. “Perlage is easier because you can use basically any drill press,” Murphy says. “It’s a fairly simple process. It’s just a matter of doing it precisely for it to look good. So we made a little table for turning and moving it around, so it can do nice, precise circles. We’re having equipment made to do a specific job. We’ve been able to build good equipment reasonably. We’re a little company, so we have to be practical.”

In 2008, Murphy says, “I made the final tweaks and changes and we ran 100 sets of parts.” He and his team decorated and finished the movements by hand and assembled the watch. The first series of RGM Caliber 801 watches, with a seconds subdial at 6 o’clock, debuted later that year in steel cases with a 42-mm diameter and 10.5-mm thickness. They proudly proclaimed their origins inside and out: “Lancaster, Penna” is printed at the bottom of the seconds subdial and “Lancaster, Penna, U.S.A.” is engraved prominently on the movement’s bridge.

It’s worth noting that all of the guilloché work on Caliber 801 watches — and all RGM watches — is done in-house. Murphy is something of a guilloché freak. His shop has five guilloché machines, unheard of in the watch world: three antique rose engine machines and two straight line machines. It was a major investment; the machines cost between $12,000 and $25,000 each. He stocked up on guilloché machines a few years ago, when his Swiss supplier of hand-made guilloché dials suddenly refused to sell to him anymore. With the help of a master engine-turner in Switzerland, who agreed to teach him, Murphy mastered the art and has passed it on to his colleagues.

In January, Murphy unveiled a second series of Caliber 801 watches with a larger stainless-steel case (43.3 x 12.3 mm) made in Lancaster County. All RGM watches with this case are designated as the Pennsylvania Series. Today Caliber 801 watches come in seven versions, priced from $6,400 to $9,500.

In 2010 Murphy realized another dream: he produced an American-made tourbillon. “There are a lot of tourbillons out there but no one is building one in the United States,” he says. The new MM2 caliber in the RGM Pennsylvania Series Tourbillon uses a Swiss balance, “but we build the entire tourbillon part: the fourth wheel, the carriage, all of the tourbillion parts are built here in Lancaster or Mount Joy,” Murphy says. Murphy is producing the watch in a small numbered series, as either a standard model or customized, in stainless steel ($95,000) or 18k gold (pricing on request).

Like the Caliber 801, Caliber MM2 proclaims its Pennsylvania origins. The movement is engraved with an emblem Murphy created for the piece: a “T” (for tourbillon) inside a keystone, the symbol of Pennsylvania, the Keystone State. “U.S.A.” is also engraved on a bridge. Other distinctive features of the watch include a small window on the side of the case with a view of the tourbillon mechanism, a seven-tooth winding click and wolf-teeth wheels.

Murphy looks back on his American movement adventure with some satisfaction. “Getting through that seven-year learning curve has paid dividends,” he says with a laugh. “The biggest dividend is seeing the watch come to life. The first day you see that new creation and it’s working in your hand, that’s the biggest day, it really is. That’s the biggest excitement that I have. I say, ‘Wow. There it is. It works. It’s ours. We built it.’”

This article was first published in 2012 and has since been updated with new information.

This is a beautiful time pieces .

I saw your segment on 60 Mnutes last Sunday and it brought to mind my graduation watch that has been sitting in my jewelry drawer for so many years. Is there a chance that it can be repaired???

The watch is an Elgin Delux, bought in 1952, the year I graduated.

I had it looked at many years ago when it stopped working, but to no avail.

Would very much like to hear from you regarding any guidance you might suggest.

I live in Palm Harbor, FL

Thanks, Amelia Sarne

This is really a comment about both the USA watchmakers – Murphy and Kokobold. I was born, raised and educated [at PITT] in Pittsburgh, Pennsylvania when it reality was dirty smoke filled SteelTown. So I am delighted about both of these stories. I keep urging my grandson in Seattle to go to the watchmakers school in the Community College.

My Dad inherited me a Hamilton Chronometer WWII vintage. It works fine and lives in a two wooden box case. A joy just to hold, hear and see. I wish I could afford an RGM to use and eventually inherit.

Kudos and stick to it.

Glad to know RGM is making their own movements. Roland is definitely one of American greatest watch maker! Those guilloche dial looks stunning!

Ironic that once the pocket watch supreme builders in the world, America has come down to one precision watch maker; RGM. Where the Hamilton’s, Howard’s, Elgin’s, and Illinois railroad grade pocket watches set the accuracy standard for the world, in less than fifty years we’ve lost that talent and craftsmanship.

I wish Roland all the luck in the world and hope the few watch collectors who can afford these luxury items come to value this enterprising company.

It’s truly ironic that now, mechanical watches are the most expensive watches made regardless of the fact that none are as accurate as a good $48 Timex.

Keep on time…virg

“It’s truly ironic that now, mechanical watches are the most expensive watches made regardless of the fact that none are as accurate as a good $48 Timex.”

Women notice my Patek Philippe 5119J Calatrava and after I give them my 20-second Swiss watch spiel they’re just mesmerized by it. A Timex wristwatch does NOT have that effect on women ;-)

With a starting price-point of $6,500 RGM is par with Omega and their high-end watches are, in my opinion, an equal value to similar Swiss mechanicals.

For such a small watch mfg. company to have 5 rose engines is a testament to the dedication of Roland Murphy to his craft/passion, may he succeed and his company flourish in the years to come.

That is awesome! And from my own state, and country!

Wish I could afford one, I’d wear it with great pride!!

Kudos!

That is so awesome.., and from my own state! Wish I could afford one! – I’d wear it with great pride!!

Kudos!

nice to hear ……..

VERY LIKE!

I look forward to reading more about American Watch makers!