Losing the Lube

The vacuum inside the case has another surprising effect, as the think-tank team vividly demonstrated during one of the workshops. First, a bit of science: The boiling point of water (and other liquids) is affected by both temperature and air pressure. As air pressure decreases, so, too, does the temperature at which the liquid boils. We associate boiling liquids with high heat, because most of us only encounter boiling water at normal air pressure. However, at high altitudes, where air pressure is lower, water boils at lower temperatures. For example, on top of Mt. Everest, water boils at about 167 degrees Fahrenheit, compared with 212 degrees at sea level. If you reduce the air pressure enough, water will boil at room temperature.

At this point, you may see the problem Cartier faced: Given the 99.8-percent vacuum inside the ID Two case, any oil on the movement would instantly boil and vaporize. To demonstrate this (see photo next page), Cartier’s development team placed a drinking glass filled with water, and a small air pressure gauge, under a heavy glass dome. A short tube ran from the dome to an air pump. As the pump removed the air inside the dome, bubbles began forming in the water. By the time the pressure gauge indicated about 25 millibars, the water was bubbling furiously – it was boiling at room temperature. (Normal air pressure at sea level is about 1,000 millibars.)

If oil would boil inside the ID Two case due to the vacuum, the movement must be able to function without oil. That bit of logic led Cartier to develop a movement that is entirely lubricant-free. We’ll look at how the company achieved that by following the energy flow from the mainsprings (there are four of them, as we’ll soon see) to the escapement.

Springing Ahead

Metal springs have been used to power timekeepers since the 15th century, and the formula for the metal alloy used in today’s mainsprings dates to the 1970s. The technology is old, and inefficient. In traditional watch movements, the mainspring and barrel are major sources of friction and wear. As the spring unwinds, it rubs against itself and the barrel. In the ID Two, Cartier sought to both reduce friction and store more energy without enlarging the barrel. Its research led it to create the world’s first fiberglass mainsprings.

You may associate fiberglass with rigid products like boat hulls and sports-car bodies, but it is also used in strong, flexible products like fishing rods and pole-vaulters’ poles. Properly formed, fiberglass is both highly elastic and endowed with a remarkable ability to store energy. The fibers in Cartier’s recipe are optical quality and only 9 microns in diameter. The fibers, and the spring geometry, are unique to Cartier, and it says its new springs produce 30 percent more energy than traditional metal alloys. Judging by simulated wear tests, Cartier says the springs will last 10 years.

To reduce friction, the springs are coated with a thin layer of Parylene, the trade name for a pore-free, extremely smooth polymer film. The barrels receive an ADLC coating. ADLC is an acronym for “amorphous diamond-like carbon,” which is extremely hard and smooth. The Parylene-coated springs and ADLC-coated barrels have the same coefficient of friction as lubricated alloy springs, but with no lubricant to dry out (or boil away).

Finally, the barrels themselves employ a non-traditional construction. The ID Two features two “Duolevel” barrels sitting side by side. Each barrel houses two springs, one above the other, for a total of four mainsprings in the movement. Inside the barrels, the springs unwind in opposite directions, and the barrels release their power serially (one after the other).

Cartier says its mainsprings provide a flatter torque curve than traditional springs, and that the resulting power output is more consistent than that found in a movement with a constant-force escapement, because the new mainsprings treat the “constant force” problem at the source. (A constant-force escapement is designed to give uniform impulses to a balance and hairspring, and thus prevent changes in rate caused by variations in the driving force.) Cartier told us that its springs will work very well in perpetual calendar and jump-hour watches because the springs have sufficient power to activate the displays even near the end of their power reserve. It sounds as if we will see these new springs in a perpetual calendar or jump-hour watch one day.

An Efficient Train System

The gear train in a typical mechanical movement is plagued by friction and inefficiency. Imprecise positioning of the wheels, outdated manufacturing techniques, the weight and coefficient of friction of the materials, the meshing of gear teeth and the turning of pivots in jewels add up to a 25-percent loss of power delivered from the barrel to the escapement, according to Cartier. To address these inefficiencies, Cartier has taken several steps, resulting in a gear train that bears little resemblance to one found in a traditional movement.

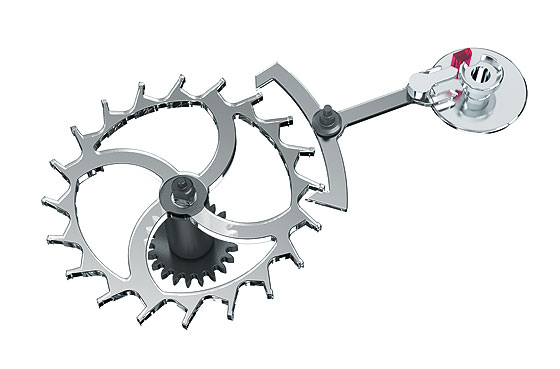

The most obvious change is the addition of a planetary gear system just before the escapement. In this system, as shown below, a central wheel is accompanied by moving shafts that orbit around the center together with the gears and pinions to which they are affixed. Pinions connect the outer ring gear with inwardly positioned teeth. Cartier claims this arrangement offers smaller teeth loads and more efficient transmission of energy.

In addition to the new construction, DRIE (deep-reactive ion etching) fabrication technology allows parts to be created with single-micron accuracy. Weight and friction concerns are addressed by replacing steel and brass with carbon-crystal-coated silicon, which Cartier says is 60 percent harder and 70 percent lighter than steel. The new materials are also non-magnetic and corrosion-resistant. To further reduce friction, the tips of the titanium pivots use optimized geometries, and an ADLC coating promotes low-friction operation.

Cartier says these improvements reduce gear-train energy losses to one-fifth of those found in standard movements.

Escaping the Ordinary

Traditional mechanical escapements require manual adjustments to make them as precise as possible. Much of this attention is necessitated by the materials employed and by imprecise manufacturing techniques. Balance wheels are not perfectly balanced, so adjustments are made by turning screws or removing material from the rim. Imperfect hairsprings are adjusted by altering their length. Non-identical parts lead to manual mating of suitable pairs. Pallet stone positions are adjusted to match escape wheels. Once these adjustments are made, the escapement’s performance is still affected by the state of the lubricants.

Cartier’s ID Two carries over key escapement components from the ID One, Cartier’s 2009 concept watch, and they illustrate what modern manufacturing techniques and materials can achieve.

The one-piece anchor (with no separate pallet stones) and the escape wheel are etched to 1-micron accuracy using DRIE, resulting in components that work together perfectly every time. These components are fabricated from lightweight carbon crystal, and the anchor pallet surfaces are plasma polished, resulting in an ultra-smooth finish that requires no lubricant. The escape wheel’s light weight makes it easier to stop and start eight times per second, as it does in a movement operating at 4 Hz. The balance wheel’s titanium pivots have optimized geometry and a friction-reducing ADLC coating that is a mere 2 microns thick.

The hairspring is crafted from a material called Zerodur – a glass ceramic that exhibits almost no thermal expansion. Each spring is perfectly formed, and so does not require adjustment during movement assembly, or during the life of the watch.

These components combine to produce an escapement that Cartier says is durable, highly accurate, and that never needs to be adjusted.

The Final Score

It’s always nice when a series of improvements to a product can be boiled down to a single number – something we can all relate to, and something that makes a difference in the real world. Fortunately, we have such a number – it’s 32. The ID Two offers 32 days of power reserve in a movement that measures only 31.5 by 10.45 mm, housed in a 42-mm case. Other efforts at month-long autonomy have yielded timepieces suitable only for retailers in the Land of the Giants.

In creating the ID Two, Cartier set three goals for itself: storing maximum energy in a minimum space, increasing energy transmission efficiency, and reducing energy consumption. Meeting all three goals would naturally result in an extended power reserve. A regular-size watch that runs for 32 days on a single wind represents an undisputed triumph.

Not surprisingly, Cartier has filed six patents on the ID Two: two on the Duolevel barrels, one on the differential gear train, and three on the Airfree vacuum technology.

Like the companies that produce futuristic concept cars for major auto shows, Cartier says it has no plans to commercialize the ID Two. Rather, the advances it embodies will find their way into future production watches. The clear cases alone should keep some collectors up at night, awaiting their arrival.

Receive all the news, features and reviews from WatchTime for free! Sign up to our free weekly newsletter and get all the news delivered to your inbox.

Since the movement in the case is in a vacuum, I wonder how noticeable the tic-a-tic-a-tic-a will be. Of course there will be some sound transmission through the structure of the watch but I’m curious if it is any quieter when held to the ear. I seem to remember seeing experiments where an alarm clock is placed in a bell jar and its ringing becomes inaudible as a vacuum is applied.

I only hope this technology and the fine styling that they have given it, will be coming to market. I would hate to see our premier manufacturers go the way of the car manufacturers and tease us every two or three years with a magnificent concept that never sees the light of day.

This is a great concept, as running a Balance Wheel and Escapement inside a vacuum should result in an increase in amplitude. Physics tells us here that an increase in amplitude here is a direct result of a decrease in friction as there is less resistance against the Balance Wheel and Escapement, therefore the movement should suffer less wear and tear. To further reduce wear an tear, Cartier would also be in a position to reduce the movement’s vph. On the other hand this concept could be used to create an amazingly fast vph chronograph movement. I wonder if TAG Heuer have this ideology in mind regarding the further advancement of its Mikrogirder 2000 and beyond!